Pressure transmitters with wear-free ceramic CERTEC® measuring cells can compensate for temperature shocks

What Grandma already knows

The cooking and canning of food is an old, but very reliable method of preservation. A short period of heating is enough to kill off bacteria and prolong shelf life. Our grandparents mastered this simple principle a long time ago. So what problems could it pose for a state-of-the-art production line with precise filling technology and extremely accurate weighing and portioning of vegetable soups?

A systematic error

It was a pressure transmitters' measured values that didn’t always make sense to one particular canned food manufacturer. At one stage in the production of clear vegetable soups, the level measurement dropped again and again to an abnormally low value within seconds. A quick diagnosis led them to believe that the problem was simply random deviations in the sensor, but it turned out that there was a systematic error. The same error always occurred whenever large quantities of frozen vegetables were dosed into the boiling water.The “clicking toy frog” effect

We need your consent

This content is provided by an external provider. If you activate the content, personal data may be processed and cookies set.

A strong duo for hygienic applications

Clean measuring methods from the clean room

When it comes to food, we always expect the ingredients we use to be flawless and well-selected. Equally important for our confidence as consumers is the manufacturing process, where each component plays an important role. Ultimately, the entire production chain is only as strong as its weakest link. The high quality of the ceramic-capacitive CERTEC® measuring cells begins in the special clean rooms at VEGA. Here, the special air circulation and access precautions ensure that there are no more than 352 particles with a size less than 0.5 µm per cubic metre, in the room. That's ten thousand times lower than our cleanest living quarters, on average. In this completely dust-free environment, the CERTEC® measuring cells are printed and fired using thick film technology. The process ensures that the glass solder connection, connecting the base body of the measuring cell and the ceramic diaphragm, achieves a precise gap of less than a hair's breadth, with a tolerance of +/-1 μm.

Ceramic sensors that follow the food trend

This type of pasteurisation usually means heating to 75° C for a few seconds, while freezing means flash or shock freezing: down to -30° C in within seconds. VEGARBAR 82 pressure transmitters with CERTEC® ceramic cells perfectly meet the increasing requirements on temperature robustness and provide the basis for reliable, highly accurate measurement. This, in conjunction with the extreme durability of their high-performance ceramics, makes them practically unrivaled in the world of instrumentation. VEGABAR 82

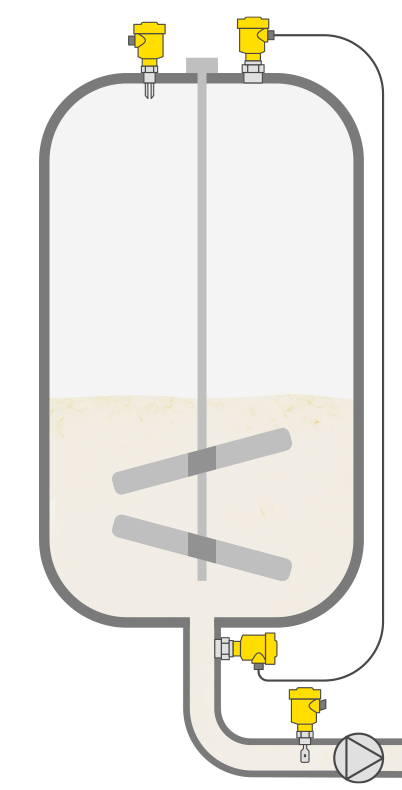

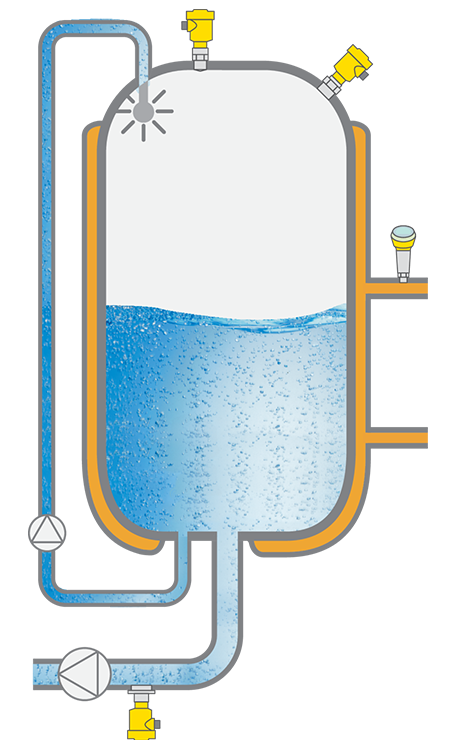

Application examples with CIP and SIP cleaning.

Tanques de armazenamento de álcool

Medição de nível de enchimento e detecção de nível pontual no tanques de armazenamento

Para a aplicaçãoTanque de leite cru

Medição de nível de enchimento, medição de pressão e detecção de nível limite no tanque de leite cru

Para a aplicaçãoTanque de armazenamento de água ultrapura

Medição de nível e pressão no armazenamento de água ultrapura (Water for Injections)

Para a aplicaçãoWe need your consent

This content is provided by an external provider. If you activate the content, personal data may be processed and cookies set.

Exportar este artigo

Baixar como PDFCompartilhar post

Comentários ({{comments.length}})

{{getCommentAuthor(comment, "Anônimo")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}