Radar technology can now be used even in small containers

The big advantage of radar technology is its ability to measure under different and changing process conditions across a variety of media. However, up until now, the use of the sensors in small vessels was very limited, because sensors were not available with the necessary small process fittings as well as not achieving the accuracy and measurement certainty required at very close range.

Guided radar has been used as an interesting alternative, but it quickly reaches its limits in applications with very strong product movement, agitators and the very high demands on hygiene.

Although the close range of radar sensors is not limited by a dead band, the previous technologies were often subject to limitations because the interfering signals from the antenna system could cause accuracy problems or even obscure the echoes from the product surface.

The solution

The high frequency of VEGAPULS 64 not only facilitates the use of significantly smaller process fittings, it also ensures significantly better measurement performance when the sensor is used in small vessels. The large sensor bandwidth produces very narrow echo signals, which enables a significant increase in measurement accuracy, even at close range.

The use of new antenna technologies for 80 GHz frequency range has assisted in reducing the interfering signals at close range – the result is significantly higher measurement reliability right in front of the antenna. Due to these significant performance enhancements, VEGAPULS 64 can also be used in smaller vessels.

The benefits

- Accurate, universal radar technology can be used in very small vessels

- Non-contact, hygienic and wear-free measurement

- Easy replacement of existing technology thanks to the process fittings

Expert tip:

The strength of the reflected signal is determined by the medium and the size of the antenna. Level measurement directly in front of the antenna is more challenging when the medium reflects poorly and the antenna is very small. When measuring oil products with a ¾" antenna system, it is a good idea to maintain a minimum distance of 10 - 15 cm which can be achieved with a stand-off nozzle, but if larger process fittings are used, this distance can be considerably shorter.

Applications

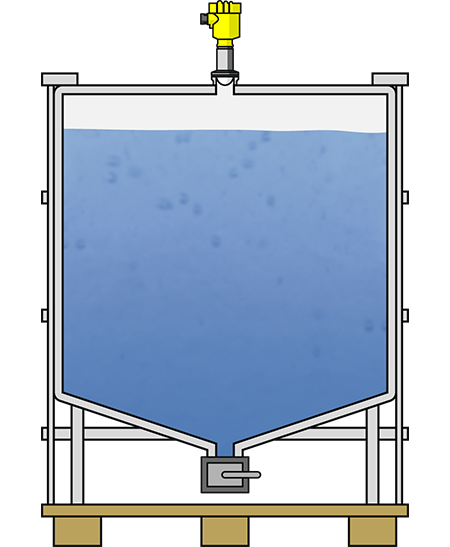

Tanque IBC (metálico)

Medição do nível em recipientes para transporte de líquidos

Em muitos processos de produção no setor químico, são necessárias pequenas quantidades de diferentes substâncias químicas para melhorar as propriedades de certos produtos. Os produtos são disponibilizados diretamente nas áreas de produção em reservatórios pequenos e transportáveis. A medição do nível de enchimento garante o abastecimento do processo em andamento.

Seguro

Medição exata até o fundo do reservatório

Econômico

Sensor rápido e fácil de montar

Uso fácil

Visualização direta dos valores medidos

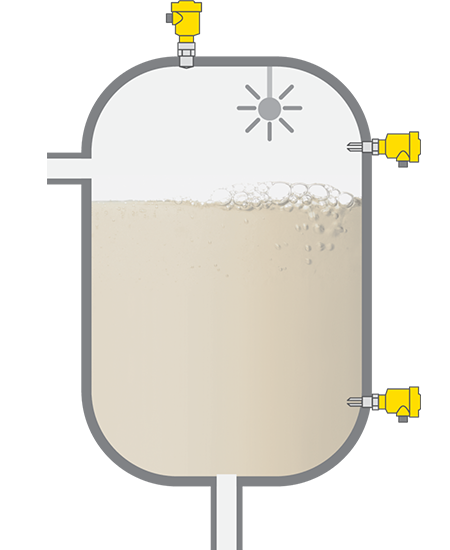

Batch filler vessel

Level measurement in the batch filler vessel

The small batch filler vessels around 1 m high and 60 cm diameter alongside the production facility supply the filler heads of the tank. The products vary from conserve to peanut butter to chocolate spread, with varying viscosity and temperatures. The product density is also changing from each batch. The level system is required to enable an optimal filling of jars.

Reliable

Measurement independent of density and viscosity

Cost effective

Accurate level measurement optimises use of jars and medium

User friendly

Simple setup

Tanque de armazenamento de produto de limpeza do sistema CIP

Medição de nível de enchimento e nível limite no tanque de armazenamento de produto de limpeza do sistema CIP

A limpeza das plantas de processamento na indústria farmacêutica ocorre no âmbito da limpeza "Cleaning in place (CIP)" validados, que garantem uma condição asséptica dos reservatórios de produção. Como produtos de limpeza são muitas vezes usados soda cáustica ou ácido concentrado, que são armazenados no tanque do sistema CIP e diluídos tanque de produção. Uma medição de nível de enchimento permite o estoque ideal de produtos de limpeza. A detecção de nível limite atua como proteção contra transbordo e funcionamento a seco.

Seguro

Materiais homologados conforme FDA e CE 1935/2004

Econômico

Operação livre de manutenção

Uso fácil

Montagem simples

Small containers

We need your consent

This content is provided by an external provider. If you activate the content, personal data may be processed and cookies set.

Exportar este artigo

Baixar como PDFCompartilhar post

Comentários ({{comments.length}})

{{getCommentAuthor(comment, "Anônimo")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}