Level switches for point level measurement and measuring techniques

Level switches for point level measurement and measuring techniques

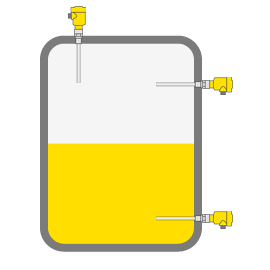

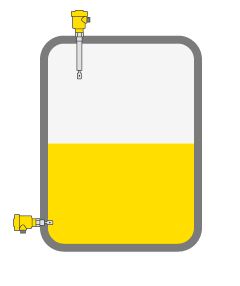

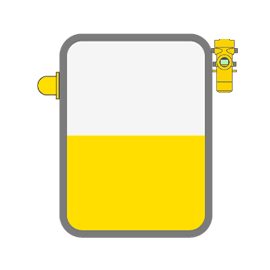

Level switch for point level detection

In a nutshell: Point level detection

In point level measurement, level switches transmit a signal when a predefined level in a tank, silo or container is reached. A switching command then starts or stops filling equipment such as conveyor belts or pumps. When their output is converted into a binary signal, level switches can be integrated into a process control system.

What methods are used for point level detection?

The following measuring principles can be used for point level detection:

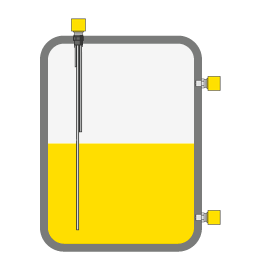

- Point level measurement with vibrating level switches

- Point level detection with capacitive level switches

- Point level detection with conductive point level switches

- Point level detection with microwave barrier

- Radiometric point level detection

Which measuring principle is the right one depends on where the level switch is to be used. We’re happy to assist you in finding the most suitable level switch for your application.

What are the advantages of VEGA level switches?

Where can level switches be used?

Typical areas of application for point level detection in the process industry are:

- Process vessels

- Storage tanks

- Silos

- Pipelines

- Overflow basins

There, the level switches serve as:

- Full detector, i.e. overfill protection: the switching command stops the filling process

- Empty detector: the switching command starts the filling process

- Dry run protection for pumps

- Leakage monitoring

- Oil/water detection

- Foam detection

- Interface detection

Level switches are used in:

- Liquids

- Sticky media

- Light bulk solids such as cement, flour, etc.

- Heavy bulk solids such as gravel, scree, etc.

- Foam

What requirements must level switches meet?

Depending on the measuring principle and sensor configuration, point level sensors from VEGA can also be used in the following areas:

- Hazardous zones and safety-related systems up to SIL2

- Chemically aggressive media

- Abrasive or adhesive media

- Special hygienic applications in the food and pharmaceutical industries thanks to certified materials and process fittings

- Extreme temperature and pressure conditions

Discover all the possible applications of point level detection in your industry

Water and wastewater

Building materials

Chemical industry

Energy

Food industry

Mining and metal production

Oil and gas offshore

Refining and petrochemical

Pharmaceutical

Ship and yacht building

Environment and recycling

Cement

Close