Good measurement, good yogurt

The yogurt producer La Fageda has found success in its 25 year history by hiring a diverse team of people from all backgrounds and abilities. Their own personal recipe has been a mix of solid personal commitment, locally-sourced ingredients, and a clever marketing concept.

The goal: Produce the tastiest yogurt. And you do that by charting your own course, even it it means veering from the production methods used by the market leaders in the food industry. La Fageda is located in the Garrotxa district, and it's one of the region's largest employers. The company has seen regular growth every year, and they've expanded their portfolio to include ice cream, jam, and desserts.

Guided wave radar measurement for strict hygiene requirements

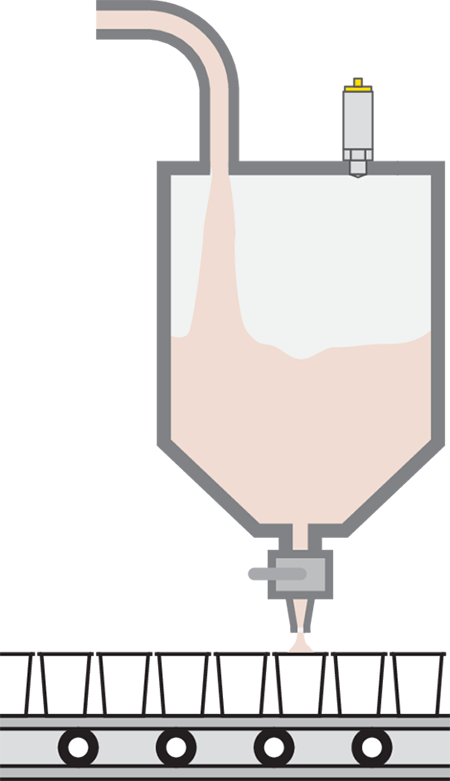

Strict requirements are placed on the filling equipment, which has to function like clockwork. This is where the yogurt is fed into the filling machine. As yogurt and various dessert varieties fill the small feed container, the level is continuously measured. A constant level measurement ensures the filling machine does not come to a standstill. Every hour, 12,000 yogurt cups are filled in the one machine, and another 20,000 in two other machines.

Until recently, there was no continuous level measurement here. They only had capacitive sensors, which only provided operators with high and low point level measurements. The company wanted to optimize the filling process, and an engineering company recommended the VEGAFLEX 81 guided wave radar sensor, which is used in many industries because of its reliability and versatility. VEGAFLEX guided wave radars can output accurate measurements regardless of temperature, pressure, and vacuum.

Supply tank of a filling machine

Level measurement and point level detection in the supply tank of a filling machine

Yoghurt is stored in the supply tank of the filling machine. Reliable level measurement and point level detection are important for maintaining the filling process. A point level sensor is also used to prevent dry running of the supply to the machine.

Reliable

Certified materials according to FDA and EC 1935/2004 regulations

Cost effective

Continuous filling process, thanks to a reliable measurement

User friendly

Simple installation and setup

VEGAFLEX is immune to foam, buildup, pressure, vacuum, and high temperatures

Inside the filling vessel, the yogurt passes through a funnel and into a container with a small agitator at the bottom, and all of this combined results in a challenging situation for level measurement instrumentation. Only a small amount of the yogurt sticks to the probe of the VEGAFLEX 81, but because of the self-cleaning system inside, this never causes any issues. The small agitator can also lead to inaccurate measurements because it causes foam to form. Fortunately, the VEGAFLEX 81 is immune to the foam, and it can still deliver reliable measuring results, which ensures the filling system runs smoothly.

Influence of condensate, buildup and foam | VEGAFLEX Series 80The strong focusing and wide dynamic range of VEGAPULS 64 ensure reliable measured values

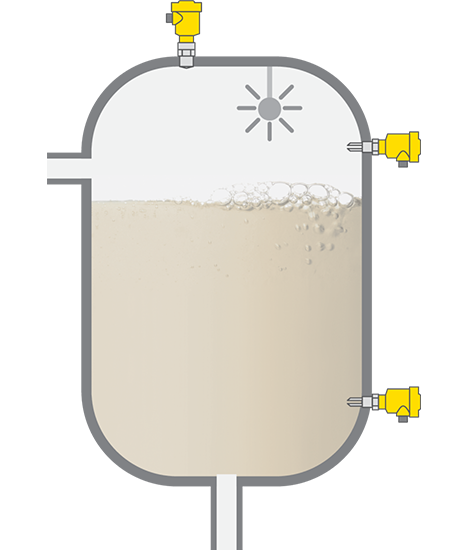

CIP systems are essential for hygienic production. VEGA sensors continuously measure the level of the cleaning agent for the cleaning and sterilization of the production equipment.

The extremely tight focusing and high dynamics of the sensor enable precise, reliable measurements in the cleaning fluid tanks. Similar to the previous application, the company never had a continuous level measuring device − only capacitive sensors that signaled the minimum and maximum level. After the installation of the VEGAPULS 64 radar sensors, these are now used as alarm sensors. Now, the company can optimize the process flow here and utilize the advantages of continuous level measurement.

Cleaning agent storage tank of the CIP system

Level measurement and point level detection in the cleaning agent storage tank of the CIP system

The cleaning of process equipment in the food industry takes place within the framework of validated "Cleaning in Place (CIP)" processes that ensure aseptic conditions in production tanks. Sodium hydroxide or concentrated acid are frequently used as cleaning agents, which are stored in the storage tank of the CIP system and diluted in the production vessel. Level measurement enables optimal storage of these cleaning agents. Point level detection serves as overfill and dry run protection.

Reliable

Certified materials according to FDA and EC 1935/2004 regulations

Cost effective

Maintenance-free operation

User friendly

Simple mounting

Related products

Related industries

Food industry

Related articles

Radar level transmitter VEGAPULS 64 measures the level in whey production

Read moreExport this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}